June this year marks the 24th "safety production month" in the country, focusing on the theme of "everyone talks about safety, everyone will be emergency - find the potential safety hazards around you". Hanas New Energy Group has carried out a series of effective safety theme practice activities with early deployment, swift action and implementation, and strives to further deepen the safety concept in the hearts of the people, enhance safety management efficiency, and continue to build a solid line of defence for enterprise safety production.

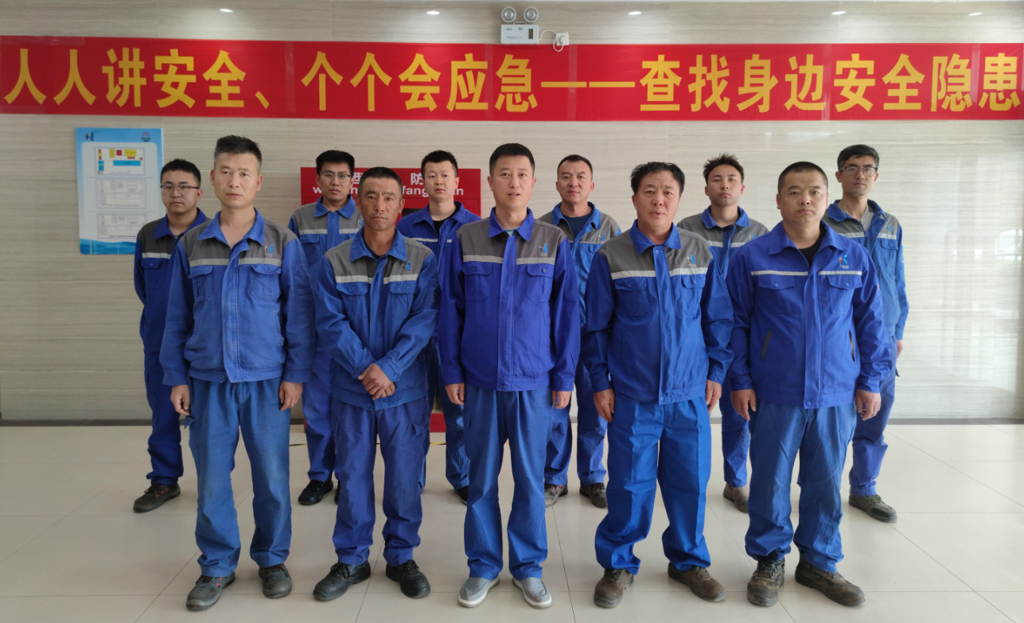

Propaganda and mobilisation, all employees promise to fulfil their promises

On the morning of May 30, the launching ceremony of the safety production month of the new energy group was held at Songbao Wind Farm, attended by the executive deputy general manager of the new energy group, Tan Chao, along with other management personnel and all employees of the safety production department. At the ceremony, Deputy General Manager Chen Zhengyu read out the "New Energy Group 2025 Safety Production Month Activity Plan", which is based on General Secretary Xi Jinping's series of instructions on safety production, and outlines the main tasks of the safety production month from five aspects: "theme idea", "organisation and leadership", "activity arrangement", "specific requirements" and "inspection and implementation", providing clear guidance for the achievement of the goal. In the resounding oath of "anti-violation, removal of hidden dangers, ensuring safety and promoting production", the participants solemnly signed the theme banner of safety production month, and jointly promised to keep in mind the mission, live up to the entrustment, and uphold the solemn commitment to safety.

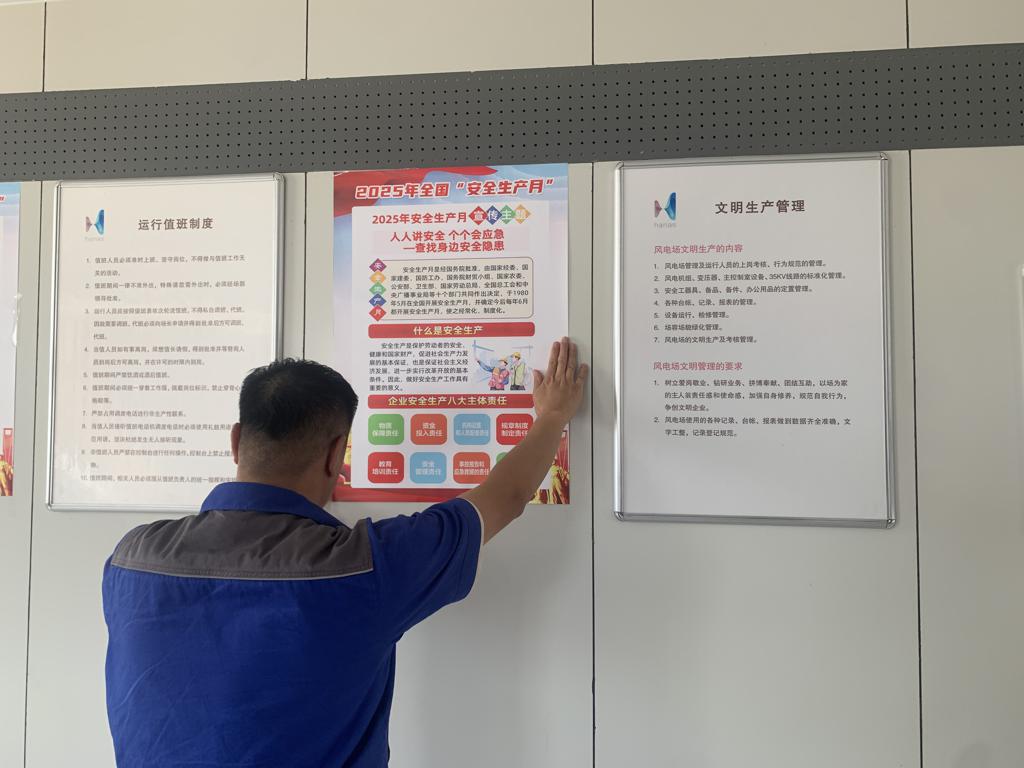

In order to create a strong atmosphere where "everyone speaks of safety, everything is for safety, and safety is always on our minds," the New Energy Group has planned ahead and started to comprehensively sort out and update the equipment labels, system signs, safety slogans, and warning signs at each wind farm station. On the day the Safety Production Month commenced, the equipment labels in the production area were standardized and orderly, the thematic promotional posters in the work and living areas were neatly aligned, safety warnings were clearly visible and accessible, and the safety concepts were firmly rooted in the hearts of the employees at all times.

Take the case as a lesson and strengthen training and education

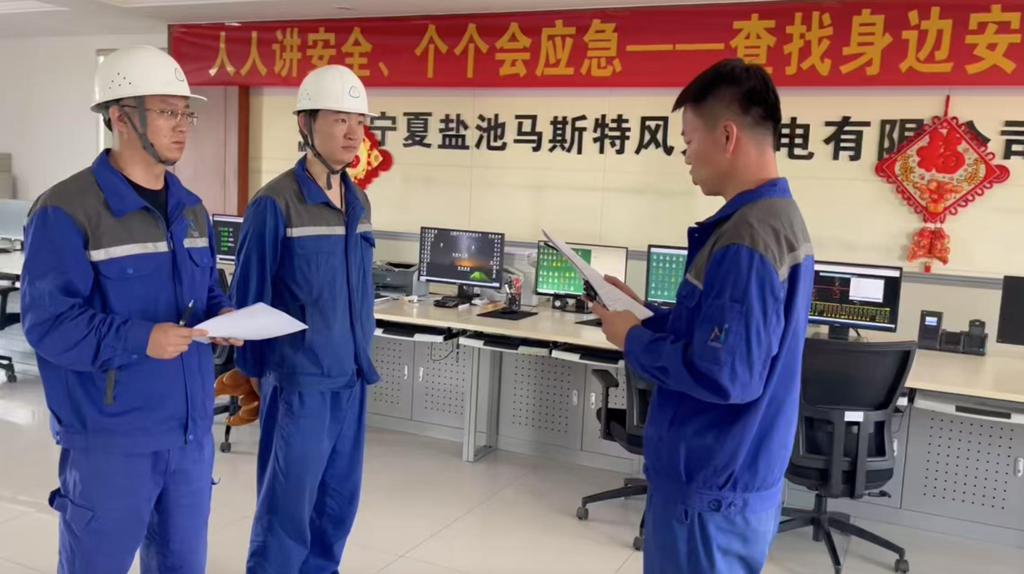

Focusing on the three themes and management objectives of "zero violations", "operation standardization" and "safety production standardization team construction", New Energy Group organised and carried out diversified training and education activities covering all employees during the safety production month. In Yinchuan station, the Ministry of Quality and Safety took the lead in holding a special training on "New Safety Production Law and the Main Responsibility of Enterprise Safety Production", focusing on the requirements of safety laws and regulations and the main responsibility system for functional departments, and continuously deepening the concept of "safety is no trivial matter, and safety is everyone's responsibility". At the production site, focusing on the three major procedures of post safety risk identification, identification of violation norms and "operation, inspection and operation", each station organises special training and full staff examinations to promote learning and use by examination, and effectively improve the safety red line awareness and risk prevention ability of front-line employees. During the period, each station also organised employees to watch warning films such as "2025 Safety Month Theme Propaganda and Education Film" and "Warning Education for Typical Accident Cases of Falling from Heights", and guided employees to analyse and find potential safety hazards, deeply learn the lessons of safety accidents, and keep in mind the concept of "safety responsibility is heavier than Mount Tai" and transform it into action.

Actual combat training to lay a solid foundation for security

During the safety production month, all wind farms and stations of the new energy group carried out a comprehensive special action for the investigation and management of hidden dangers. The quality and safety department focuses on the key links of safety management and high-risk areas such as high altitude and live electricity, and thoroughly corrects hidden dangers such as illegal command, illegal operation, and violation of labour discipline; the operation department and the maintenance department combined with the daily work, comprehensively doxxed and meticulously sorted out, from the condition of the production vehicle to the sealing and dehumidification of outdoor equipment, leaving no dead corners and checking item by item. Through two-stage, multi-level and intensively focused actions, a total of 96 potential safety hazards have been investigated at each station, with a rectification completion rate of 100%, and the safety situation is stable and improving. In order to strengthen the emergency response capabilities for extreme weather prevention, personal electric shock and other accidents, according to the deployment plan, each station organised emergency drills for all employees. The drill strictly abides by the requirements of the "Emergency Plan for Production Safety Accidents" and the "Emergency Plan for Emergencies", simulates the real accident scene, and implements it item by item in accordance with the link of "information report - response start - emergency disposal - emergency support - response termination", focusing on the familiarity of personnel with emergency plans, accident emergency standardisation and self-rescue and mutual rescue capabilities, timely discovering problems in emergency management, and urging all employees to tighten the safety chord at all times and improve the level of emergency combat.

Protect the environment and practise social responsibility

June 5 is World Environment Day, and as an influential green energy enterprise in the region, New Energy Group has always taken "guarding the blue sky and white clouds" as its own responsibility, actively practising social responsibility and making due contributions to "everyone" while strengthening safe production and caring for "small families". During Safety Production Month, each station carried out coordinated rectification of the regional environment of wind farms in combination with the investigation and management of hidden dangers. The operation team takes the station as the centre to clean up the waste left in the surrounding area of the station; during the inspection of the wind turbine, the fan maintenance team focused on removing the remaining debris around the wind turbine foundation; when the line maintenance team inspected the 84 35kV lines and 8 110kV/220kV lines in operation, they specially removed and treated white pollutants such as floating objects in the line corridor and the outer packaging of farmland drip irrigation, which not only beautified the environment but also significantly reduced the risk of line operation caused by foreign body floating.

Skills competition, deepen intrinsic safety

At the end of June, the new energy group's production skills competition commenced simultaneously at various wind farms. This competition aims to effectively assess the comprehensive skill levels of operational and maintenance personnel. Through competition, the objectives of learning, catching up, and surpassing are realised, leading to an overall improvement in the professional quality of production personnel, thereby supporting the high-quality development and safety of the enterprise. The competition is divided into two specialisations: operation and maintenance. The operational staff focus on assessing substation monitoring, operation, switching operations, and troubleshooting skills, while the maintenance staff focus on assessing wind turbine principles, inspections, maintenance, and repair skills. There will also be specific assessments for switching operations during power outages and regular maintenance capabilities of wind turbines. The competition utilises existing equipment at the wind farm, adopting a comprehensive evaluation method of "theoretical examination + practical assessment", with site managers conducting cross-checks, and department heads and responsible leaders overseeing the process. The aim is to thoroughly test the candidates' practical abilities with "real equipment, real processes, real evaluations", assessing technical talent and promoting overall skill level improvement.

As of July 1, Hanas New Energy Group has been in safe production for 5,196 consecutive days, which is a record that imprints the dedication of Hanas wind power people to safety and interprets the value pursuit of "life first". Safety is endless, and the new energy group will, as always, persevere, with a rigorous attitude, scientific methods, and pragmatic measures to continue to contribute to the foundation of safety, so that the road to development is broader.

Safety management is endless, and responsibility is enduring and strong