Safety is the lifeline of high-quality development of enterprises, and must always be the primary task throughout the whole process of production, operation and management. Since 2024, Hanas New Energy Group has resolutely implemented the group's safety management policy and instructions, insisted on taking safety responsibilities to heart, shoulders and hands, coordinated the main business units such as the quality and safety department, operation department, and overhaul and maintenance department, carefully organized, solidly promoted, and took multiple measures at the same time, unswervingly guarded the safety red line, weaved a tight safety net, built a safe and reliable suitable environment, and laid the foundation for completing the annual production and operation tasks and objectives and achieving sustainable development.

Vigorously carry out safety training to strengthen the foundation

In order to improve employees' safety awareness and practical skills, in 2024, Hanas New Energy Group will continue to carry out diversified safety training and education with the production site as the main place. The training activities focus on the main aspects of safety management theory and methods, safety operation specifications and standards, practical skills of safety hazard investigation, safety situation analysis and typical accident cases, and the training content is highly targeted, practical and timely. Through a total of 20 training and education, 7 practical activities and 745 training assessments, the examination and training were organically combined, and the theory and practice were promoted and unified, and the expected goal of strengthening the foundation was well achieved.

Strict on-site supervision and inspection to escort

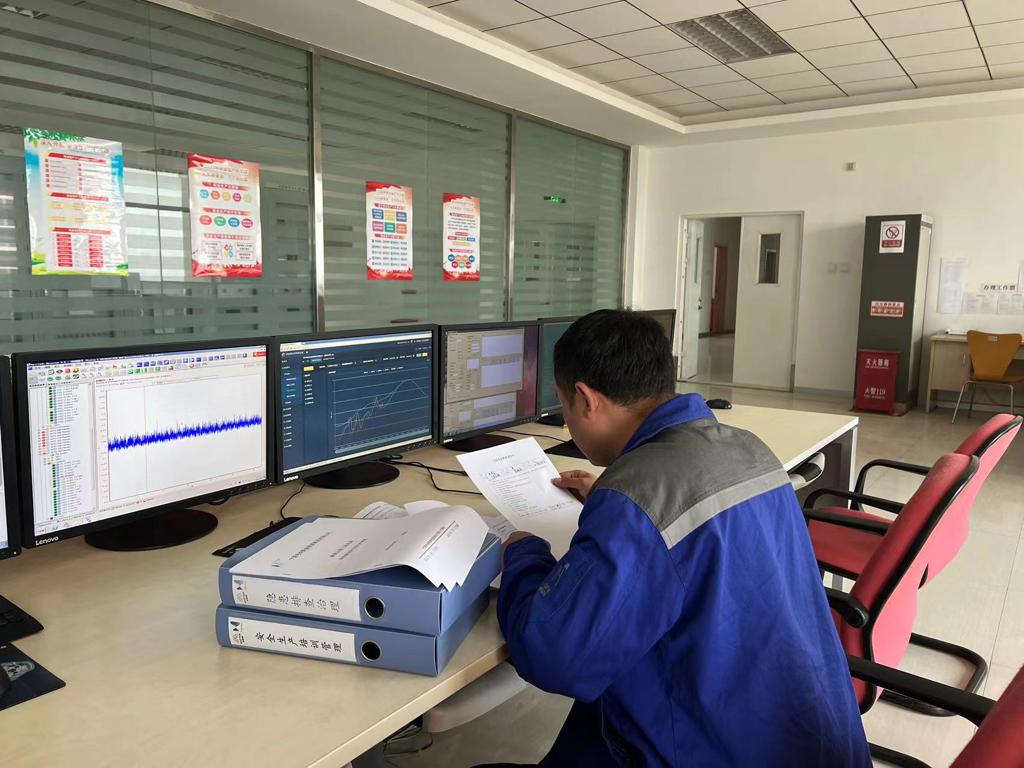

In view of the actual situation that there are many operation points on the production site, wide area, strong crossing, and easy to breed safety risks. In 2024, the quality and safety department of Hanas New Energy Group will do its best to continue to deepen and take root in the production line, and carry out uninterrupted safety supervision and inspection on the overhaul and maintenance of power generation, transmission and substation equipment. During the inspection process, the personnel of the quality and safety department not only ensure the full implementation and complete implementation of various safety rules and regulations and safety measures through "hand-in-hand demonstration", "face-to-face guidance" and "point-to-point tracking", but also enable the operators to correct the possible unsafe behaviors in a timely manner, and further strengthen the hazard identification ability and risk management and control awareness of operation and maintenance personnel, effectively promote the steady improvement of the overall safety management level of the enterprise, and make the safety management work more effective.

Pay close attention to the implementation of the "two votes" and standardize management

The "two votes" are a key part of the safety management of power enterprises and an important guarantee. In 2024, Hanas New Energy Group will organize and set up a special working group to focus on standardizing the implementation of "two votes" at the production site in response to the main problems summarized in the management practice over the years. Since the beginning of the year, a total of more than 400 work tickets and operation tickets have been sampled, from whether the overall face of the ticket meets the management requirements, to whether the listed safety measures are missing or mistakenly filled, and then to whether the safety measures are in place, until the completion of the work is completed, whether the two ticket end procedures are complete, so as to realize the whole link to grasp the fine management. During the inspection process, the quality and safety department simultaneously carried out the "two votes" filling error correction analysis, commented and explained the problems that are easy to confuse, easy to ignore and easy to make mistakes, and effectively ensured that the basic safety management work is not out of shape, out of shape, and not out of form, so as to drive and promote the implementation of other safety management measures.

Comprehensively investigate hidden dangers and prevent them before they occur

Hanas New Energy Group has always adhered to the basic policy of "safety first, prevention first, and comprehensive management", and in 2024, it will combine daily hidden danger investigation with special inspections to comprehensively carry out the investigation and management of risks and hidden dangers in equipment and facilities. Since the beginning of the year, a total of 350 potential safety hazards have been investigated, rectified and eliminated, and a number of specific tasks such as the maintenance, maintenance and supplementation of major safety equipment and facilities, the effectiveness inspection and replacement of fire-fighting facilities, and the regular inspection of insulation tools and appliances have been completed, effectively curbing the "signs of hidden dangers" and effectively preventing the occurrence of safety production accidents.

Up to now, Hanas New Energy Group has been in safe production for 4,892 consecutive days, which is not only an achievement, but also a spur. In the future, the new energy group will always tighten the safety chord and will not relax for a while, and strive to build a more solid safety foundation with more accurate, powerful and pragmatic measures, so that the safety bottom line will be more stable, and make due contributions to the high-quality development of society and enterprises, and the life and health of employees!